Complete Design & Prototyping Solutions

JLM Machining Inc. is able to design and build complex weldments. Our skilled staff members are well trained to produce innovative designs which will enable our customers to have their product specifications maximized at an economical price.

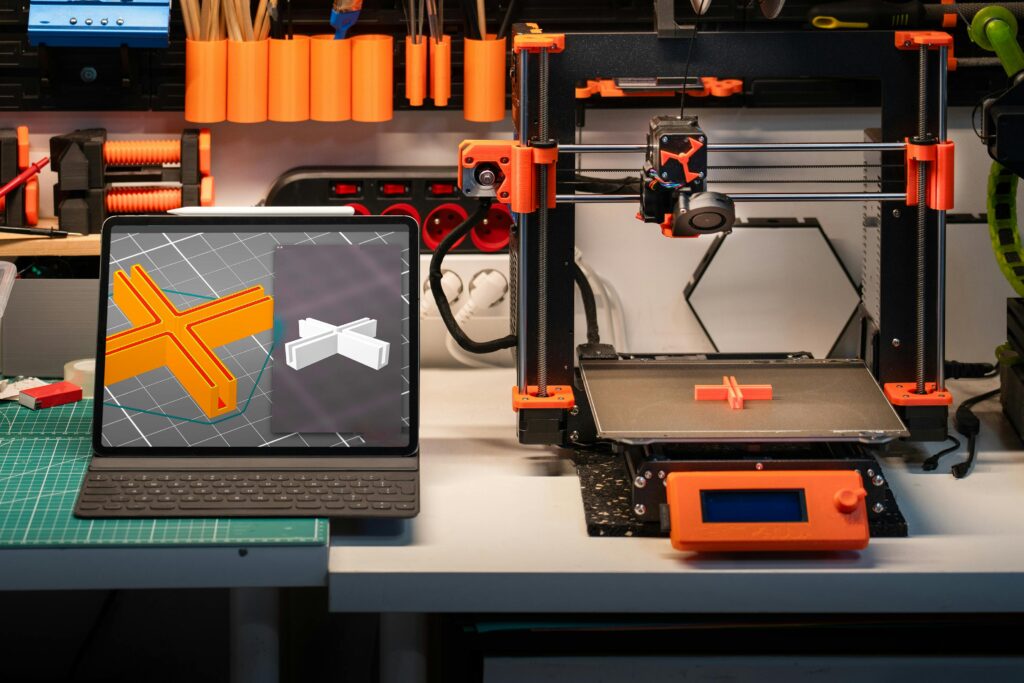

At JLM, we provide support services from the pre-prototype stage through to production. We have staff members who are trained to use SolidWorks and the 3D modelling technology. In most cases, by using this technology, a design can be optimized for manufacturing so labour and material expenses can be cost-effective.

3D Modeling Capabilities

Our Experienced 3D Modeling Experts can bring your ideas to reality in seconds. We can make sure that your machines work before being in production.Capabilities

- 3D Modeling and 2D Drafting.

- Best in class Modeling Software with friendly UI.

- If you cannot come to us, we will come to you to print your ideas on a canvas.

Prototypes That WORK

- In-House Testing and Trialing

- We conduct in-house testing and trials of the prototype before delivery.

- We ensure the finished product will arrive at the customer’s facility and be completely ready for its intended purpose.

- We guarantee that our professional team has the knowledge and experience to complete your project successfully.

- We can meet the expectations of various demanding industries.

How to Get Started

Step 1

Contact us about your project for a estimate via the form below

Step 2

Attach your drawing for us to view. If you don’t have one we can assist in creating a drawing

Step 3

We contact you to pick up your project or notify you for delivery information

Step 4

You receive your brand new design and prototypes

We help cut costs and improve part specifications through design for manufacturability

Our goal is to find success in helping you succeed in your supply chain goals. One of the ways we do that is by partnering with design engineers and mechanical engineers on the front end of projects. We help review products and look for cost drivers and deficiencies in the part design to help improve the the effectiveness of parts and improve the overall project costs.

Once we review part design we can also assist with prototypes. This allows for design changes and proper testing to assure you are happy with the products. After the prototypes are made and proven we then have everything we need to enter into production and have the ability to manufacture repeatable parts at scale.

What Is Design for Manufacturing (DFM)?

DFM stands for Design for Manufacturing and is an engineering practice for designing products that can be produced more efficiently at less cost. DFM will allow potential problems to be addressed during the design phase which is the least expensive phase to implement changes.

JLM Machining Inc. works closely with many of its clients in the Design for manufacturing stage to address potential challenges which may be present in the initial product design. Some areas of focus may include Product Design, Material Types, complex geometry, and allowable tolerances. All of these factors, when optimized can lead to the overall reduction of manufacturing costs as well as increased manufacturing efficiency.

The goal is to work side by side with our clients to provide any insights and/or recommendations while we transition a project from the design to reality.

How to Access or Custom Design Prototyping Services ?

Backed by over 35 years of experience and over 80K completed projects, JLM meets the needs of diverse industries for clients across North America and overseas. Our convenient location in the Heart of Brampton along the Highway 410 corridor facilitates fast shipments throughout the rest of Ontario and the bordering American states.